Nanocrystalline alloy cores are increasingly being applied in high-frequency power transformers due to their unique material properties, which offer several advantages over traditional core materials like ferrite or silicon steel. Here are the key reasons why Fe-based nanocrystalline cores are suitable for high-frequency power transformers:

1. High Magnetic Permeability

Nanocrystalline materials exhibit extremely high magnetic permeability, which allows for efficient magnetic flux conduction. This property is crucial for minimizing core losses and improving transformer efficiency, especially at high frequencies.

2. Low Core Losses

At high frequencies, core losses (hysteresis and eddy current losses) become a significant challenge. Nanocrystalline cores have very low hysteresis losses due to their fine-grained structure and low coercivity. Additionally, their thin laminations reduce eddy current losses, making them ideal for high-frequency operation.

3. High Saturation Flux Density

Nanocrystalline metal materials have a high saturation flux density (typically around 1.2-1.3 T), which is higher than that of ferrites. This allows the transformer to handle higher power densities without saturating, making it suitable for compact and lightweight designs.

4. Excellent Thermal Stability

Iron-based Nanocrystalline cores maintain their magnetic properties over a wide temperature range, ensuring stable performance even under varying operating conditions. This is particularly important in high-frequency applications where temperature fluctuations can affect performance.

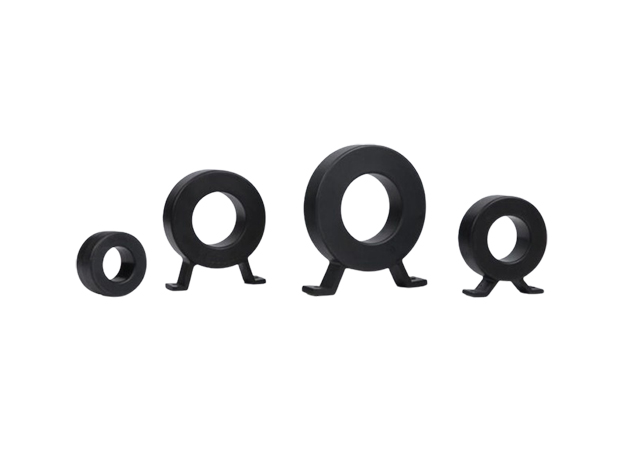

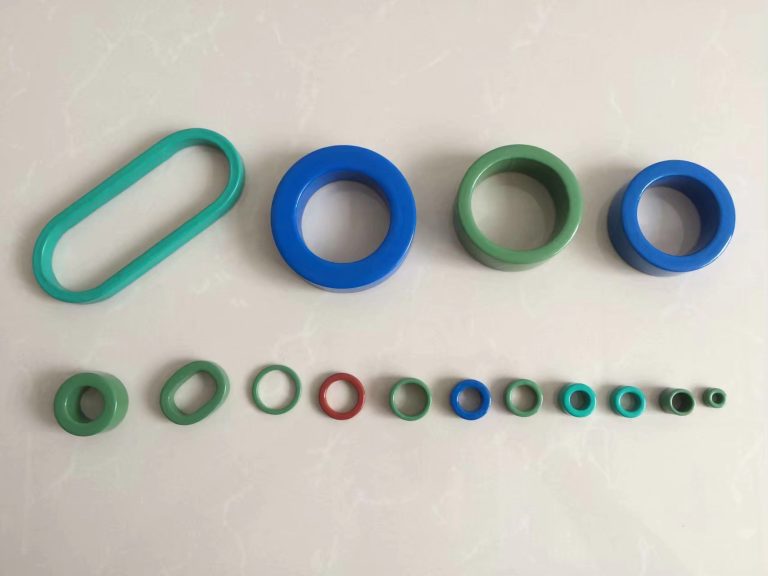

5. Reduced Size and Weight

Due to their high permeability and low losses, nanocrystalline magenetic cores enable the design of smaller and lighter transformers compared to those using traditional materials. This is a significant advantage in applications where space and weight are critical, such as in aerospace or portable electronics.

6. Wide Frequency Range

Nanocrystalline cores perform well across a broad frequency range, from a few kHz to several MHz. This makes them versatile for various high-frequency applications, including switch-mode power supplies, inductors, and transformers.

7. Improved Efficiency

The combination of low core losses, high permeability, and high saturation flux density results in transformers with higher efficiency. This is particularly beneficial in high-frequency power conversion systems, where energy efficiency is a key concern.

8. Reduced Electromagnetic Interference (EMI)

The excellent magnetic properties of nanocrystalline cores help in reducing electromagnetic interference, which is critical in high-frequency circuits where EMI can be a significant issue.

Applications in High-Frequency Power Transformers:

Switch-Mode Power Supplies (SMPS): Nanocrystalline cores are used in high-frequency transformers for SMPS, enabling compact and efficient designs.

Renewable Energy Systems: They are employed in inverters and converters for solar and wind energy systems, where high efficiency and reliability are required.

Electric Vehicles (EVs): Nanocrystalline cores are used in onboard chargers and DC-DC converters for EVs, where high power density and efficiency are essential.

Telecommunications: High-frequency transformers in telecom equipment benefit from the reduced size and improved performance of nanocrystalline cores.

In summary, nanocrystalline cores are well-suited for high-frequency power transformers due to their superior magnetic properties, low losses, and ability to operate efficiently at high frequencies. These characteristics make them an excellent choice for modern power electronics applications.