Amorphous ribbons are thin, flexible strips of metal made from amorphous alloys, which lack a long-range crystalline structure. This unique structure gives them several advantageous properties:

- High Strength and Hardness: They are stronger and harder than many crystalline metals.

- Excellent Magnetic Properties: They have low core loss and high magnetic permeability, making them ideal for applications like transformers and inductors.

- Corrosion Resistance: They resist corrosion better than many crystalline metals.

- Flexibility: Despite their strength, they are flexible and can be bent without breaking.

Manufacturing Process of amorphous ribbon

Amorphous ribbons are produced using rapid solidification, where molten metal is cooled at rates of about 1,000,000°C per second, preventing crystal formation.

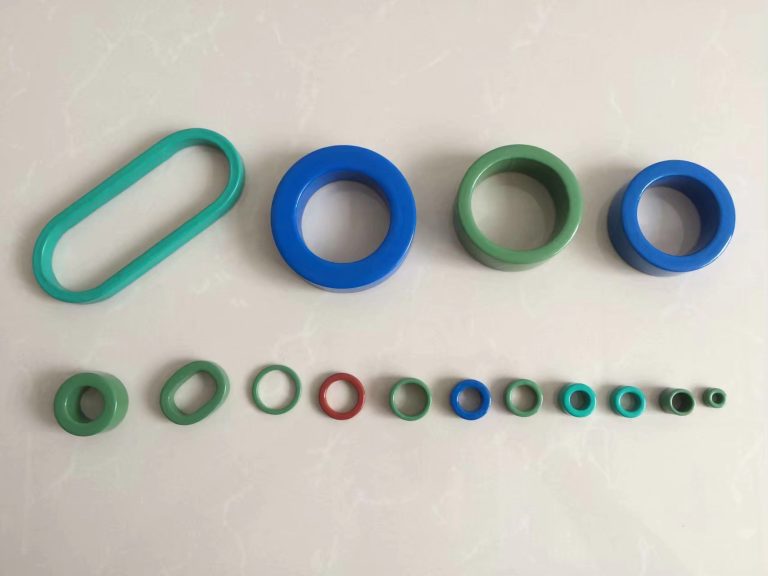

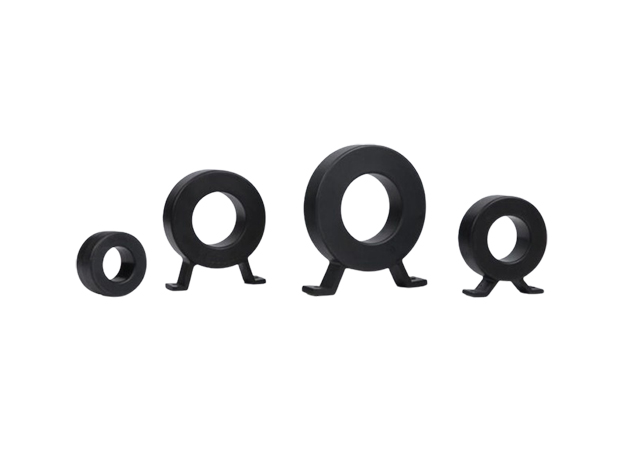

Applications of amorphous strip

- Magnetic Cores: Used in transformers, inductors, and sensors.

- Sensors: Employed in magnetic sensors and security devices.

- Electronic Article Surveillance (EAS): Found in anti-theft tags.

- Energy Efficiency: Used in high-efficiency transformers to reduce energy loss.

Advantages Of amorphous ribbon

- Energy Efficiency: Lower core losses improve transformer efficiency.

- Durability: High strength and corrosion resistance enhance longevity.

- Flexibility: It can be used in various shapes and applications.

Disadvantages of amorphous strip

- Cost: More expensive to produce than crystalline metals.

- Brittleness: It can be brittle and prone to cracking under stress.

In summary, amorphous alloy ribbons are valuable in industries requiring high efficiency, durability, and specific magnetic properties, despite their higher cost and brittleness.