1) Make sure there is good ventilation around the winding machine and no debris buildup.

2) Check that the power plug of the winding machine is safely grounded and ensure that the various components of the winding machine are intact.

3) Turn on the winder control panel and start the system.

4) Select the appropriate winding method and set the relevant parameters.

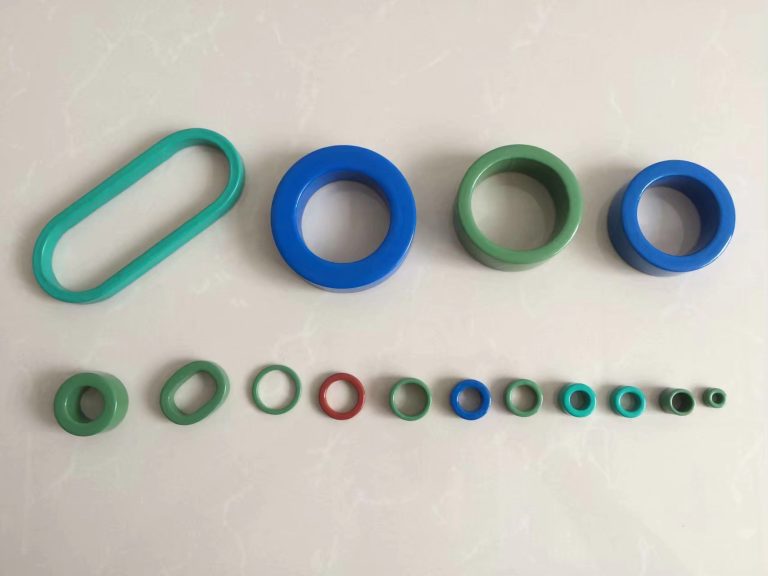

5) Prepare the material to be wound and confirm that the material quality meets the requirements.

6) Check the running status indicator of the winding machine to ensure that the running status is normal.

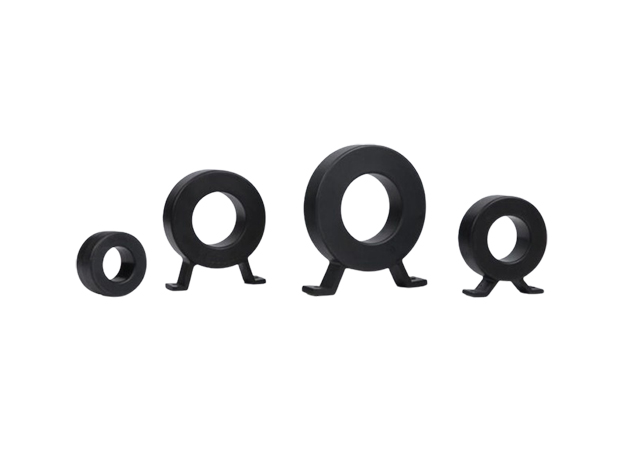

7) Press the start button to start the winder and produce the amorphous cores or nanocrystalline cores.

8) During the winding process of nanocrystalline cores, closely observe the running condition of the winding machine.

9) If you need to adjust the winding parameters, you can press the phase key at any time to adjust.

10) After finishing the winding work, press the stop button to turn off the main motor of the winding machine.

11) Turn off the power switch and disconnect the winding machine from the power supply.

12) Perform necessary cleaning and maintenance work on the winding machine to ensure that the machine is in good working condition.